Detection of chromium 6 in heated lubricants on stainless steel

Detection of chromium 6 in heated lubricants on stainless steel

Chromium-6 compounds, or ‘chromium-6’ in short, are harmful to health. The main use of these compounds is in anticorrosion paints, but they also occur in other applications as we will see below. Detection of these compounds in a simple way is important to prevent the risk of exposure to chromium-6. In our laboratory, we carried out a study of heated anti-seize pastes on stainless steel. The toxic chromate formed as a result of these heated anti-seize pastes was easily and clearly detected using the MATinspired® TK11® Chromium-6 Detection Test Kit. Mechanics or quality engineers can easily perform this test themselves by rubbing an acid moistened test swab over the metal surface. A red/purple discolouration of the test rod indicates the presence of chromium-6, and the test swab remaining orange indicates that no chromium-6 is present.

What are anti-seize pastes?

Anti-seize pastes are lubricants used against the seizing of, among other things, steel bolts, nuts and other threaded connections. This makes these joints easy to disassemble. Some anti-seize pastes are temperature resistant – often above 1000°C – and also prevent the joints from seizing after they were heated at high temperatures. These anti-seize pastes are often used in gas turbines and wind turbines, among other applications. These lubricants may contain, for example calcium hydroxide or sodium silicate. The problem with these lubricants is that during heating, chromium from the stainless steel is converted into chromates. Chromates contain hexavalent chromium, and are therefore highly toxic, and pose a health risk when used.

Results of the TK11® Chromium-6 Detection Tests

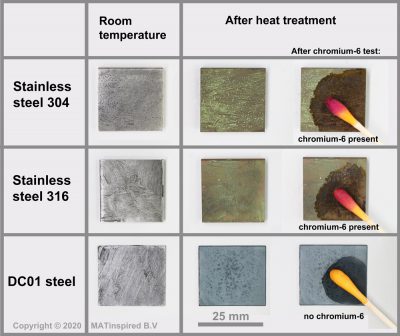

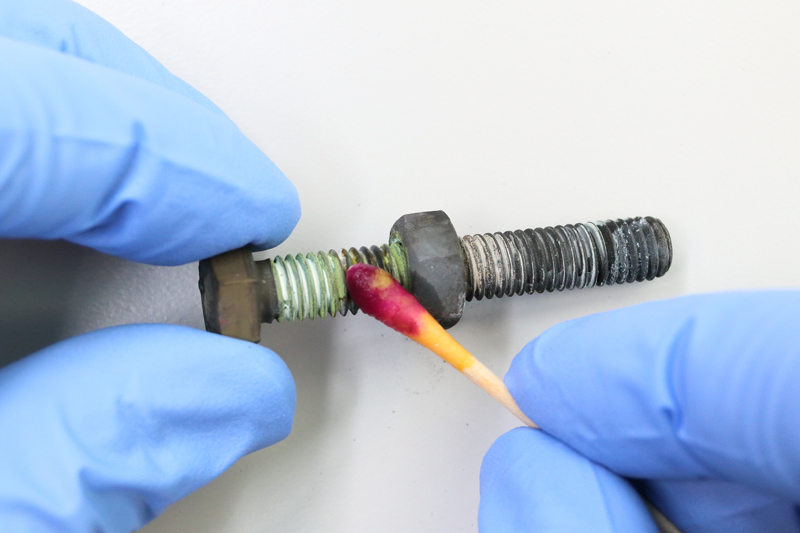

In our laboratory we coated stainless steel 304 and 316 pieces with a thin layer of anti-seize paste containing calcium hydroxide, and then we heated them in an oven at 900°C for 1 hour. During this time period, the lubricant was able to react with chromium from the stainless steel, as happens in practice with heated machine parts. Afterwards, the surface of the metal has a slightly yellowish colour (see Figures 1 and 2) corresponding to the colour of calcium chromate (CaCrO4). When subsequently tested using the TK11® test, the test swabs clearly turn red/purple (see Figure 1 and 2), indicating that chromium-6 is present on the surface. Using the TK11® Detection Test Kit it is therefore easy to detect chromium-6 formed in heated lubricant on stainless steel.

As a reference, we also measured stainless steel 304 and 316 pieces which were coated with a thin layer of anti-seize paste without heating. In this case, the TK11® test remains orange, indicating that no chromium-6 has been formed. This was also to be expected because the lubricant has not yet been able to react with the chromium from the metal. Heated anti-seize paste on steel DC01 also results in the TK11® test to remain orange (no chromium-6), because there has been no chromium present in this metal with which the anti-seize paste could have reacted (see Figure 1). Therefore, the TK11® Detection test does not give false positive results in the presence of materials that do not contain chromium-6. As a reference we also measured stainless steel 304 and 316 pieces which we heated for 1 hour in an oven at 900°C without the anti-seize paste. These blank tests show no yellowish discolouration of the stainless steel surface, and the TK11® test also remains orange, indicating that no chromium-6 has been formed. These reference tests indicate that heat treatment of stainless steel and anti-seize paste individually do not yield chromium-6, but that the combination of anti-seize paste with heat treatment of stainless steel does indeed show the presence of chromium-6.

Figure 1: Examples of pieces of steel (with a thin layer of anti-seize paste) after heat treatment, and the results of the TK11® Chromium-6 Detection Test.

Figure 2: Example of a stainless steel 304 (A2) bolt and nut with anti-seize paste after heat treatment. The formed yellowish chromate is clearly visible. The TK11® Chromium-6 Detection Test swab clearly turns red/purple, indicating that chromium-6 is present.